Choosing between single-phase and three-phase power is one of the most common — and most confusing — decisions when planning an overhead power distribution system.

Many projects don’t start with a clear answer. Some spaces mix lighting, receptacles, and equipment loads. Others evolve over time, shifting from light-duty workstations to higher-demand machinery. This guide explains the practical differences between single-phase and three-phase Track Busway systems, helping you understand which configuration fits your voltage requirements today — and how to plan for changes tomorrow

What’s the Difference Between Single-Phase and Three-Phase Power?

Single-phase uses one hot and a neutral—great for everyday loads like lighting and outlets. Three-phase uses three hots (120° apart) for smoother, higher-capacity power—ideal for big machines and HVAC.

Key takeaways

- 120V single-phase (line-to-neutral) supports most outlets, tooling, and lighting loads.

- 208V single-phase (line-to-line) powers equipment that requires 208V without a neutral.

- 208V three-phase provides balanced power for motors, HVAC, and heavier machinery.

- A standard 208Y/120V panel can supply all three from the same Track Busway run.

- Track Busway enables phase balancing across A/B/C for efficient load distribution.

Why single-phase is the workhorse

- Most facility loads are 120V, so you’ll have many more 120V drops than 3Ø drops.

- A three-phase busway can support more total 120V devices by spreading them across A/B/C phases.

Where three-phase still wins

- Smoother power for motors and big machinery.

- Higher capacity per circuit for large loads.

How Track Busway Distributes Common Voltages

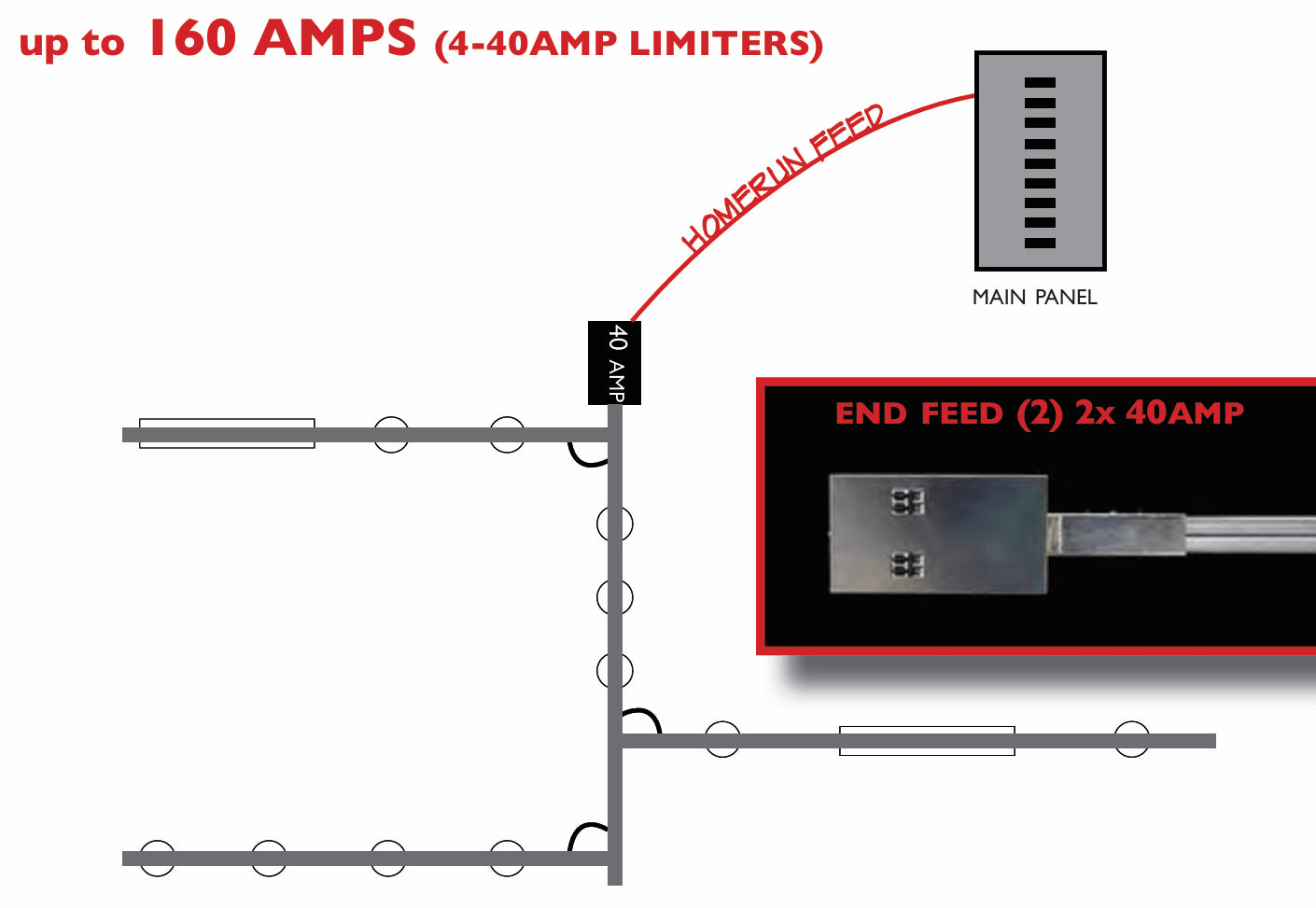

Track Busway functions as an overhead power backbone, allowing 120V, 208V, and 208V three-phase circuits to be tapped anywhere along the run without predetermined window spacing or rewiring

120V single-phase (line-to-neutral)

- Perfect for most devices and receptacles.

- Balance drops across A/B/C phases for even loading.

208V single-phase (line-to-line)

- Useful for equipment rated 208V without a neutral.

208V three-phase

- Best for heavy machines and large HVAC compressors.

Aluminum vs. USA TrackBusway™️: Phase Selection.

Traditional aluminum track busway

- Tap-off units are often keyed to a specific phase or phase-pair.

- Changing from Phase A to Phase B may require a different tap unit.

USA TrackBusway™️ (flip-fit plug-ins)

- Field-select the phase (or phase-pair) by rotating the plug-in—no special keyed fittings.

- Faster installs, easier load balancing, fewer unique parts to stock.

| Traditional Aluminum Track Busway | USA TrackBusway™️ |

|---|---|

| Tap-off units are often keyed to a specific phase or phase-pair. | Field-select the phase (or phase-pair) by rotating the plug-in — no special keyed fittings. |

| Changing from Phase A to Phase B may require a different tap unit. | Faster installs, easier load balancing, fewer unique parts to stock. |

Double-Deck Option (6-Wire) for Added Capability

Need more than standard 4-wire (A/B/C + Neutral)? The double-deck configuration stacks two tracks to add conductors. That enables:

- Dedicated copper ground for sensitive equipment.

- Low-voltage control (e.g., 0–10V lighting dimming) within the same run.

- Scalable expansion without new conduit.

| Standard 4-Wire Busway | USA TrackBusway™️ Double-Deck (6-Wire) |

|---|---|

| Supports 3-Phase + neutral only. | Adds dedicated copper ground for sensitive equipment. |

| Limited to power conductors. | Allows low-voltage control wiring (e.g., 0–10V dimming) within the same run. |

| Expansion usually requires new conduit runs. | Scalable — stackable design supports future expansion without new conduit. |

120V Single-Phase Tap any single phase conductor(A, B, or C) and neutral. No keyed fittings required; select which phase to tap in-the-field. 208V Single-Phase Tap any two phase conductors(A-B, B-C, or C-A).

208V Three-Phase Tap all three phase conductors(A, B, C).

Applications and Use Cases

- Manufacturing: mix of 3Ø machines and 120V tools on one overhead run.

- Warehouses: easy adds/moves/changes as layouts evolve.

- Labs & R&D: clean ceilings, quick reconfiguration.

- Commercial & retail: lighting plus power anywhere along the run.

Summary: Picking the Right Voltage Mix

- Use 120V single-phase for most outlets and lighting.

- Use 208V single-phase where equipment requires it.

- Use 208V three-phase for heavy rotating loads.

- Choose USA TrackBusway™️ for field-selectable phases and rapid changes.

- Consider double-deck when you need dedicated ground or control wiring.

Next Steps

Have questions about voltages, phase balancing, or which tap-offs to choose? Contact us and we’ll help design the right layout for your facility. You can also browse our FAQ or see real-world examples on our Projects page.