Table of Contents

Understanding Track Busway Voltage Options

Track busways are the most flexible overhead power distribution systems, but how you plug-into the correct phase(s) varies between manufacturers. All low voltage busway power distribution systems are capable of distributing up to 600 volts. Whether you need 208V 3-Phase power for motors, 120V for electronics, or 208Y for refrigeration, track busways meet your power distribution needs with one overhead system.

In this article, we’ll give you a brief rundown on how track busway systems can meet those various equipment voltages. With a clear understanding of voltage options, the choice between track busway systems becomes crucial for flexible power distribution. This blog post compares the voltage options using a traditional aluminum track busway and explains how Steel Track Busway is better; because it simplifies the installation and enhances wiring capabilities.

Maximizing Power Distribution with Track Busway Systems

Whether your supplying track busway with power from a 3-Phase or 1-phase electrical panel determines how the correct current may be distributed to your equipment.

In the US, most residential units use 120/240V single-phase panels for power distribution. Commercial buildings typically include 120/208V three-phase panels. With either panel type, the same track busway system may be supplied power.

While the wiring to the track busway system is similar no matter the panel, the voltage available to plug-in units varies between the different types of supplied power.

For example, 2 pole busway fittings will tap 208V or 240V depending on whether supplied by a three-phase or single-phase panel.

Choosing the Right Phase

Track busway systems can distribute power efficiently across multiple loads. So, how do you choose the best option for your facility? For starters, you need to have a clear understanding of voltage options.

How Does 1-Phase Power Distribution Work?

Single-phase power is the simplest, where one-phase conductor and a neutral provide a 120V power supply. This is quite sufficient for most machinery and electrical appliances, especially when supplying a system capable of two circuits as shown below.

Understanding Single-Phase Power Drops (120V)

A typical 4-wire aluminum track busway system comprises:

- Three phase conductors (A, B, C)

- One neutral conductor (N)

You can use the 4-wire aluminum track busway system for a wide range of voltage options. However, simple 120V plug-in units must arrive pre-configured to tap a certain one of the (3) phases (A, B, or C). With a 4-wire aluminum track busway design, there is no way to tap a specific phase without keyed fittings.

Single-Phase Power Drops with Steel Track Busway

Unlike 4-wire aluminum track busways, 3-wire steel track busways do not use keyed fittings. Steel Track Busway 120V fittings can simply be rotated 180 degrees in-the-field to select between the phases.

Steel Track Busway is the best option you can get for managing different voltage options. It allows for simple phase-to-neutral fittings to connect 120V equipment.

For example, please see 1-Phase Drop Cord product below.

So installations become easy, faster, and cost-effective with Steel Track Busway.

How Does 3-Phase Power Distribution Work?

The type of power panel used in a commercial space is typically a 3-Phase model. It is called a 3-Phase panel because 3-Phase conductors (A, B, and C) are connected to deliver 208V power phase to phase.

And yet, most equipment does not require 208V three-phase power. Typically 208V power is only required for motors. Therefore, often single-phase track busway systems are more effective for distributing power from a 3-Phase panel.

Below is a comparison between single or double-deck busway supplied from a 3-Phase panel.

Understanding Three-Phase Power Drops (208V)

Three-phase equipment is powered from connecting all three phase conductors (A, B, and C), delivering 208V phase-to-phase.

The continuous, balanced power flow of three-phase systems is ideal for motors. With Steel Track Busway, all 3 phases are tapped with a plug-in unit's factory installed whip fitting. For example, please see 3-Phase Drop Cord product below. With double-deck track busway overhead, this power drop supplies electricity to 3-Phase motors.

Understanding 208Y v 208V PowerDrops

Please keep in mind 208V power is different from the more common 208Y. Three-phase track busway is not required to tap 208Y. Single-phase Steel Track Busway already includes (2) hot wires, so you can power 208Y equipment from single phase track busway.

Benefits of Single-Phase over Three-Phase

While the 3-Phase track busway might come across as the most complete solution, the single-phase system has several advantages.

When powering single-phase equipment, each conductor is capable of carrying a system’s maximum amperage. For example, a 40 amp 3-Phase track busway system is capable of 120 amps if powering single-phase equipment.

In contrast, a 40-amp three-phase system can only supply 40 amps total of 208V three-phase equipment. Since most equipment in commercial settings can operate on single-phase power, a three-phase track busway system can support 3x more single-phase equipment than if powering three-phase equipment.

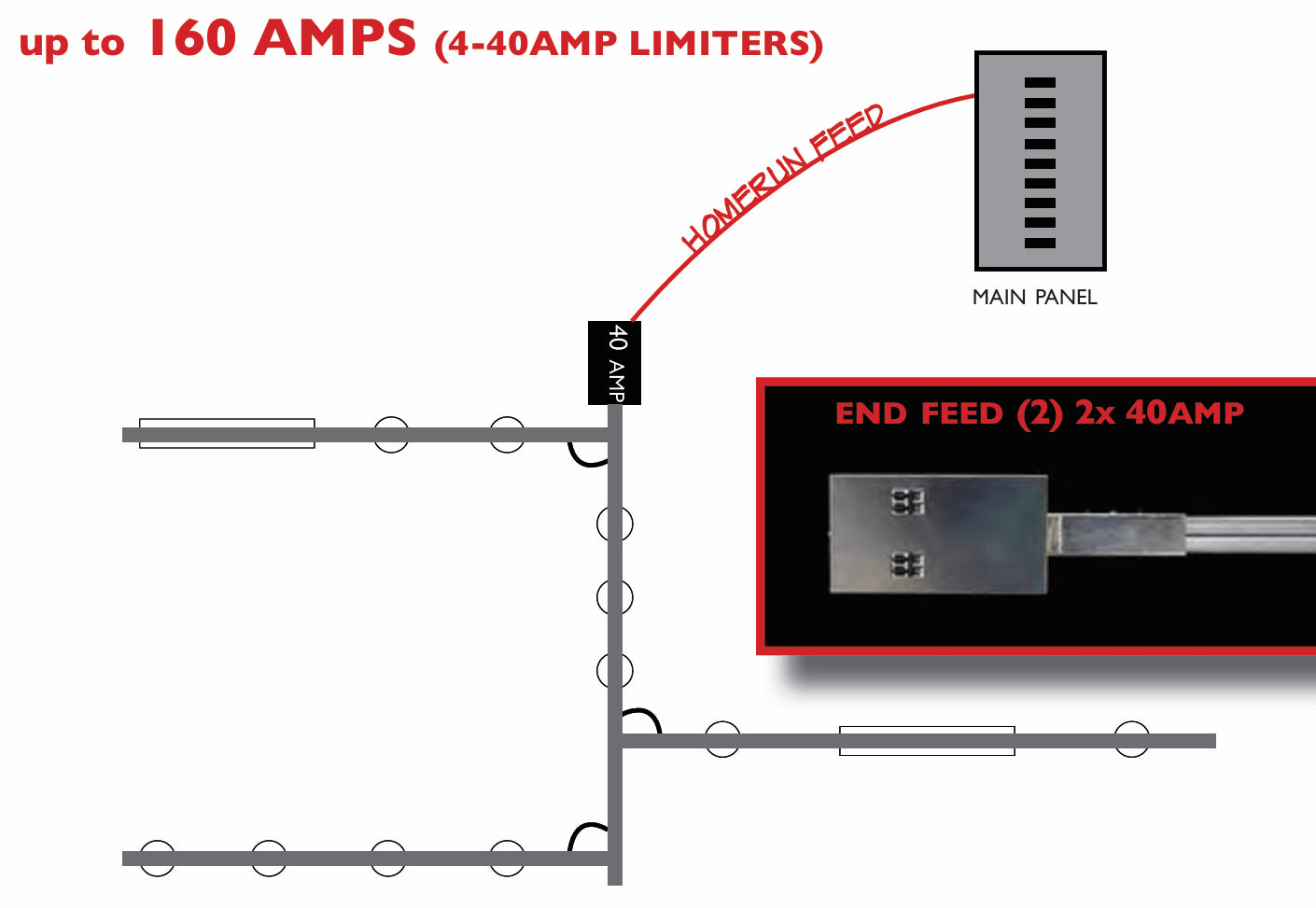

In fact, you can stack the single-phase Steel Track Busway system to distribute up to 160amps (4x40amp single circuits).

Differences between Track Busway manufacturers?

Track busway systems can be classified into aluminum or steel-based. From our observation, we have found that Steel Track Busway systems are the much better choice because they greatly simplify the installation process and help enhance wiring capabilities.

How Aluminum Track Busway Meets Common Voltage Options

The major drawback with aluminum track busways are the keyed plug-in fittings for each phase, which cannot be modified on site. You cannot choose between differing phase options on these keyed fittings and thus have very little room for on-the-spot adjustments in load balancing. This can increase costs/delays during installation and upgrade efforts.

Double Deck Track Busway and its Unique Advantage

Steel Track Busway's single-phase lengths may be stacked together in-the-field for additional capabilities. This stacking capability is used when additional wiring is needed; and referred to as double-deck.

Single track busway comes with 3 poles, so when you stack the two single-lengths, you form a double-deck design that includes six poles in total.

This stacking capability helps you gain flexibility like never before with traditional busway systems. It is a much better choice when you have to deal with demanding power requirements like dedicated copper grounding, or low-voltage controls.

Here is a neat little comparison table that can show you how optimal Steel Track Busways can be:

| Feature | Aluminum Track Busway | Double-Deck Track Busway |

|---|---|---|

| Wiring Configuration | 4 wires (3-Phase + neutral). | 6 wires (3-Phase + neutral + 2 extra poles). |

| Additional Wiring | Not available. | Dedicated ground or 0–10V dimming capability. |

| Grounding Capability | Shared neutral/ground limitations. | Dedicated 100% copper ground wire. |

| Low-Voltage Control | Not supported. | Supports modern lighting controls. |

| Installation Simplicity | Requires keyed fittings for 120V taps. | No keyed fittings; field connections. |

Steel Track Busway is available as a 6-wire system, whereas aluminum track busways can only support up to 4-wire systems. Double-deck busway includes two more conductors, and only available with Steel Track Busway. Finally, a busway that allows you to meet even the stringent electrical requirements.

Where Can You Use Steel Track Busways

Steel Track Busways provide an unprecedented advantage over any other track busway systems - it consists of 12-gauge steel. This cost-effective system is a good choice for a varied range of practical applications. You can use them in manufacturing facilities or office spaces in addition to data centers.

-

Data Centers

- Facilities like data centers demand 100% copper grounding, which Steel Track Busway supports with its additional wiring capacity in double-deck configurations.

-

Industrial Facilities

- Steel Track Busway is capable of powering various equipment types, such as high loads (208V 3-Phase) or medium loads (208Y single-phase).

Steel Track Busway: The Simple Solution to Voltage Options

Ready to future-proof your operations? Discover the steel power distribution system that offers durability, safety, scalability, and efficiency.

Track busway systems have become the standard for flexible, scalable, and effective power distribution in modern facilities. It has several advantages over other types of track busway systems, with its capability to support varied voltage options and modular design.

Whether ensuring robust grounding for sensitive equipment, integrating advanced lighting controls, or powering high-demand industrial machinery, the Steel Track Busway system offers unparalleled flexibility and reliability. Its modularity allows for quick reconfiguration, making it ideal for facilities that need to adapt or expand.

Upgrade your setup today with Steel Track Busway to ensure your power infrastructure is ready for today’s demands and tomorrow’s innovations. Contact us today to learn more.