Table of Contents

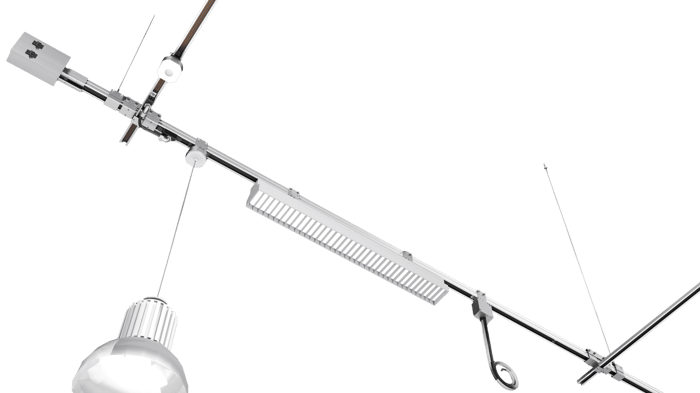

Power distribution is a critical component of any building, and especially in a dynamic space requiring flexible power drops. Trolley Busway systems have offered stable solutions for sliding power drops for decades. The track busways that have followed had pre-wired channels, but with a big flaw: aluminum housings. Steel Track Busway is a power distribution system that takes the best features from both Trolley Busway and aluminum track busway systems to offer slidable power taps.

The Legacy of Trolley Busway Systems

Trolley Busway systems earned their reputation by solving a straightforward problem: how to move power to where it’s needed. By integrating sliding trolleys and enclosed busbars, they became a go-to for manufacturing, assembly, and testing facilities.

What Makes Trolley Busway Effective:

- Sliding Power Drops: Easily repositionable along the track.

- Durable Materials: Zinc-coated steel and copper busbars ensure safety and longevity.

- Simple Setup: Modular parts make installation quick and hassle-free.

- Industrial Focus: Perfect for heavy-duty setups like steel mills or production lines.

But while these systems shine in specific applications, they’re limited in layouts to individual rows or columns. Meanwhile, track busway systems are capable of interconnected configurations to reduce feeds and ensure flexibility to add equipment in the future.

Traditional Track Busway Systems: A Missed Opportunity

Traditional track busways addressed some gaps by introducing prewired intercepts. Power drops could be added or moved, and on an interconnected configuration overhead. However, adjustments usually required tools, ladders, and lots of patience. Think of it like adjusting track lighting. Every tweak meant stopping operations, climbing up, and reinstalling components—a far cry from true flexibility.

Steel Track Busway: Flexibility Without Limits

Steel Track Busway changes everything. It’s a leap forward in modular design, combining the best aspects of both systems while eliminating their downsides.

Slidable Power Taps: Forget ladders with Steel Track Busway, repositioning a power drop is as easy as sliding it into place.

Double-Deck Modular Design: Unlike traditional track busways, Steel Track Busway’s ability to double-deck allows for all types of future changes. Whether sliding power drops or adding electrical capacity, changes can be made quickly—often without downtime.

The Steel Track Busway lengths can stack in the field to create a double deck run. In this setup, the non-electric lower deck provides the raceway for sliding, while the top deck includes the power distribution. This separation of functionality keeps systems streamlined and reduces clutter.

Imagine your facility sliding power drops into place. This modularity is ideal for spaces like open-ceiling offices, retail stores, or event venues where infrastructure must remain versatile.

Comparing the Systems

| Feature | Trolley Busway | Aluminum Track Busway | Steel Track Busway |

|---|---|---|---|

| Power Distribution | Sliding for movable power drops | Must get on ladder to re-position. | Sliding power taps on a prewired top deck |

| Modularity | Fixed design for power delivery | Only available as single-deck | Field-configurable double-deck system |

| Applications | Heavy-duty industrial setups | Data Centers | Industrial, retail, and commercial spaces |

Applications Where Steel Track Busway Excels

Steel Track Busway thrives in environments where flexibility isn’t optional:

- Retail Spaces: Use the top deck for power drops and the lower deck for AV or lighting installations.

- Industrial Facilities: Provide flexible power for machines while supporting overhead decor or tools.

- Event Venues: Quickly reconfigure layouts with plug-and-play components for lighting, signage, and power.

- Open-Ceiling Offices: Simplify the integration of power, lighting, and acoustic panels.

Wherever adaptability and integration are required, Steel Track Busway delivers.

Why Trolley Busways Can’t Keep Up with Today’s Dynamic Environments

The Verdict: Why Steel Track Busway Wins

While Trolley Busway systems solved the sliding power problem, they’re limited in layout capabilities to individual runs (rows or columns). Traditional track busways introduced prewired channels but fell short on flexibility. Steel Track Busway combines the best of both systems while adding double-deck modularity for slidable integrations. It’s a complete solution built for today’s evolving spaces.

Conclusion

For decades, Trolley Busway systems and traditional track busways have served industries well. But the demands of modern spaces require more capacity for change. Steel Track Busway offers the flexibility, scalability, and functionality to meet those demands head-on.

Contact us today to learn how Steel Track Busway can transform your power distribution setup.