Table of Contents

Track busway systems are revolutionizing how power is distributed, by providing unprecedented levels of flexibility, scalability and efficiency over the traditional methods. These pre-engineered systems are changing how power is managed overhead in all sectors, from data centers to manufacturing facilities.

What is a Track Busway?

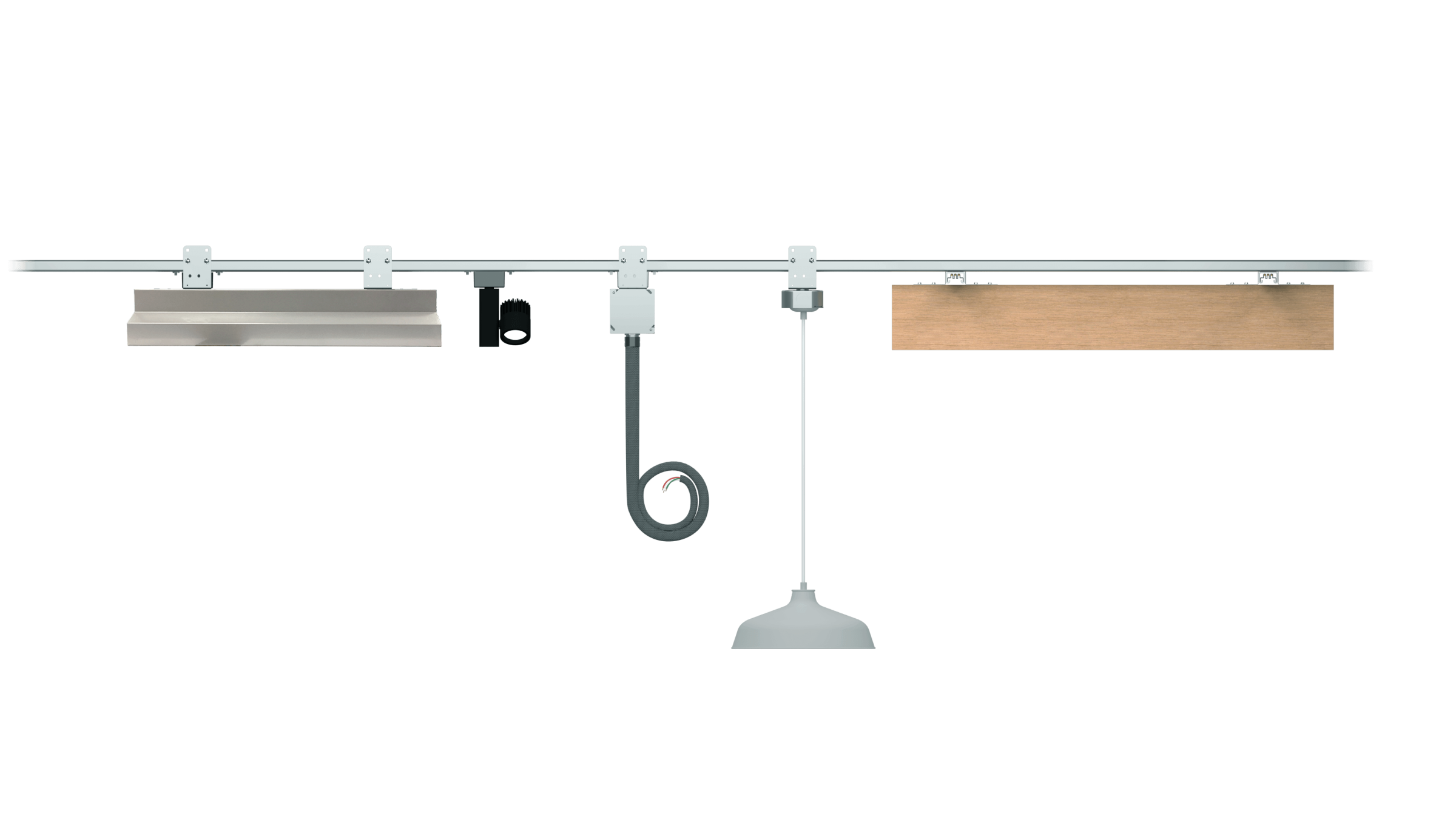

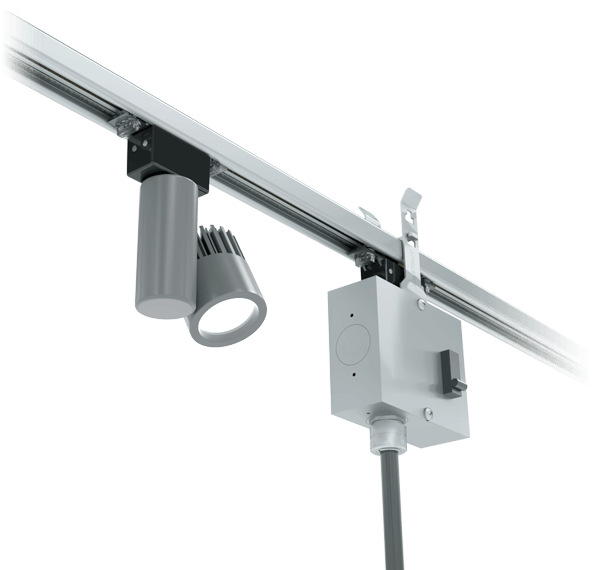

Track busway include a continuously open channel along its lengths. Plug-in units can be inserted at various locations. UL 857 listed busway systems must pass finger-safe testing. These prewired tracks eliminate the need for complex wiring and enable quick re-configurations. In addition to lengths, there are a few other components to a track busway system.

Key Components

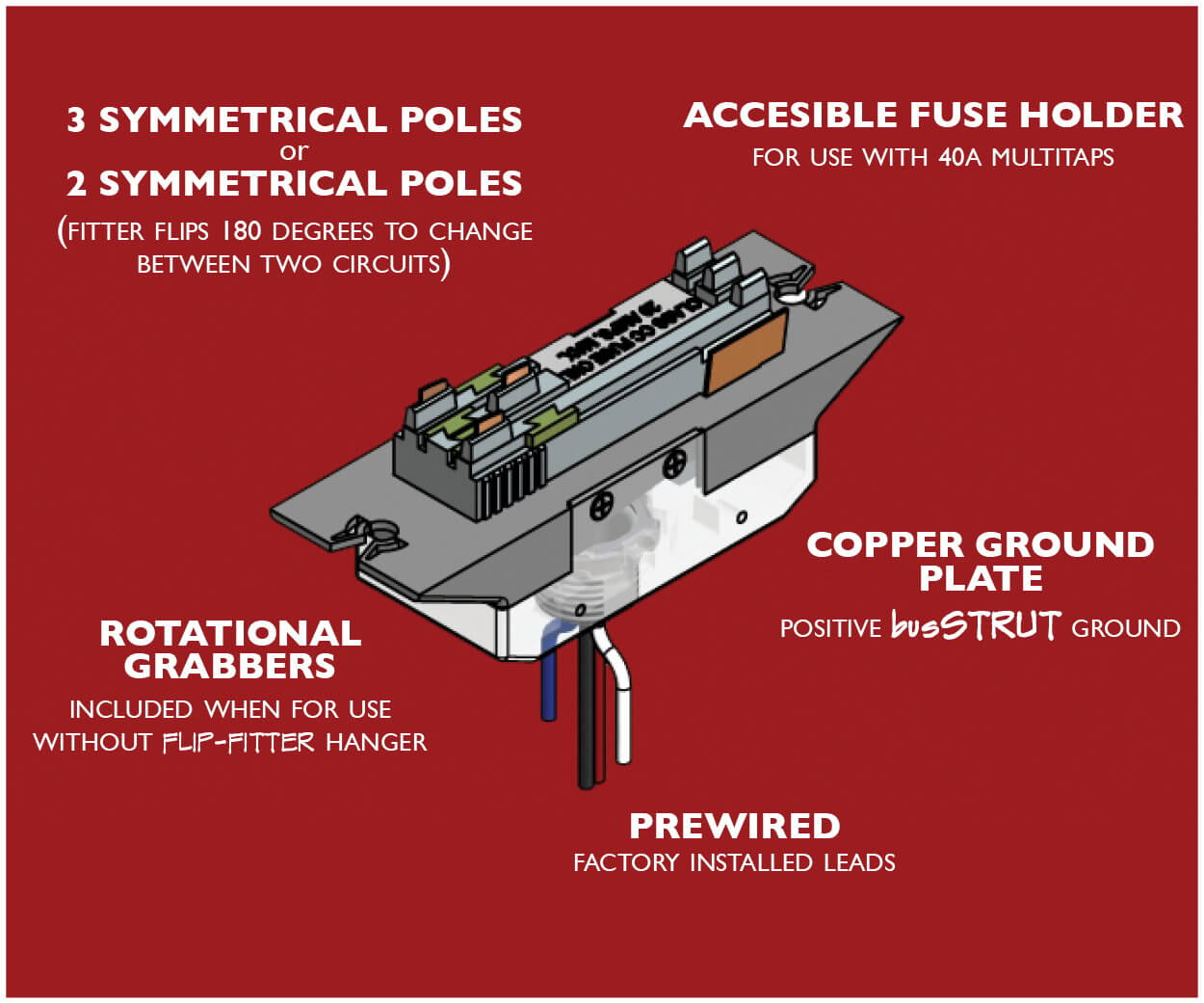

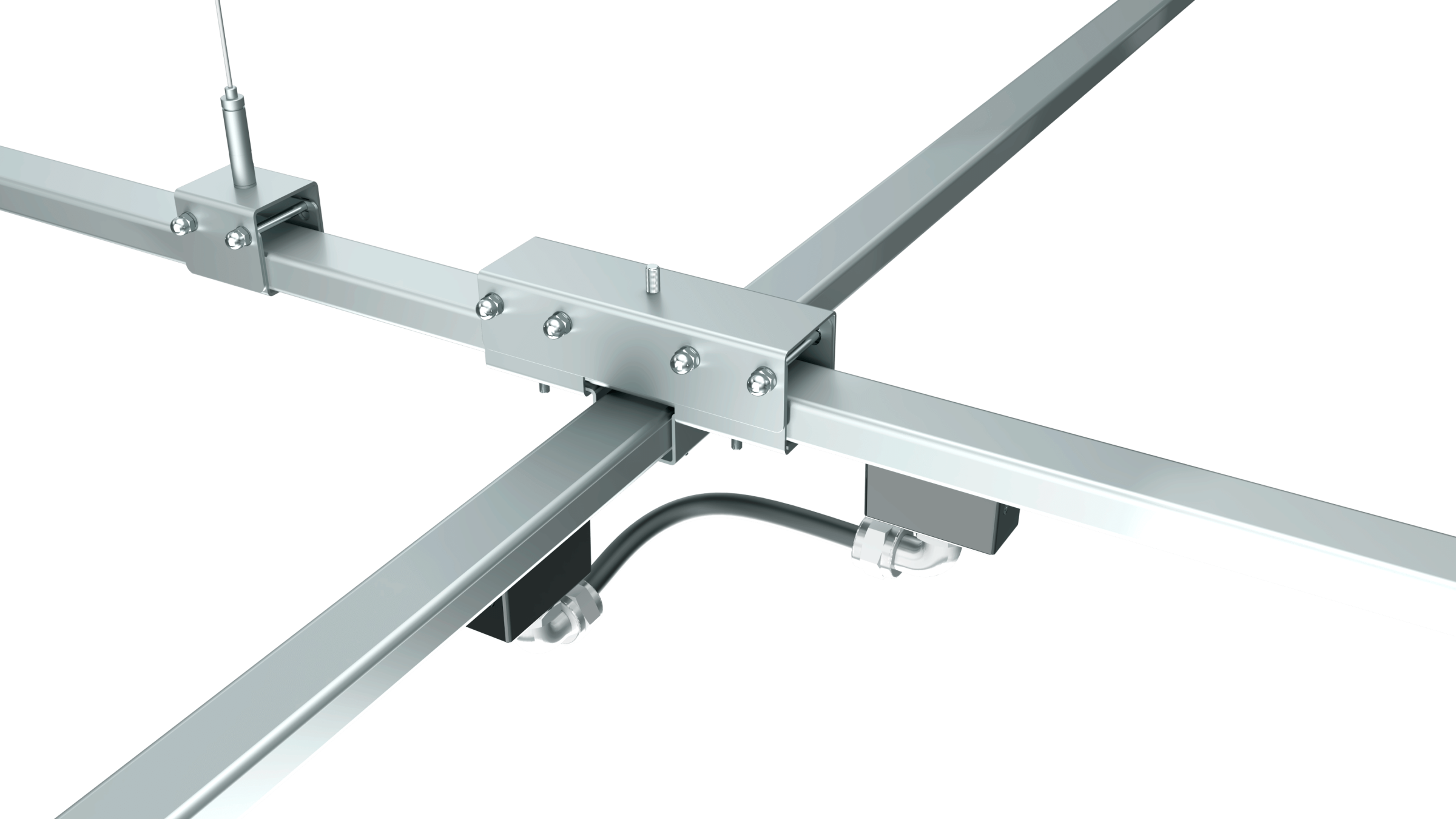

A flexible busway power distribution solution requires only joiners, hangers, and feeds with the lengths for an adaptable overhead solution. Busway fittings can be added at any point along the lengths to obtain power. These electromechanical connectors enable flexible and scalable power distribution. Typically, busway fittings arrive pre-installed on tap off units with breakered protection. Here’s a breakdown on the primary components of a track busway power distribution system:

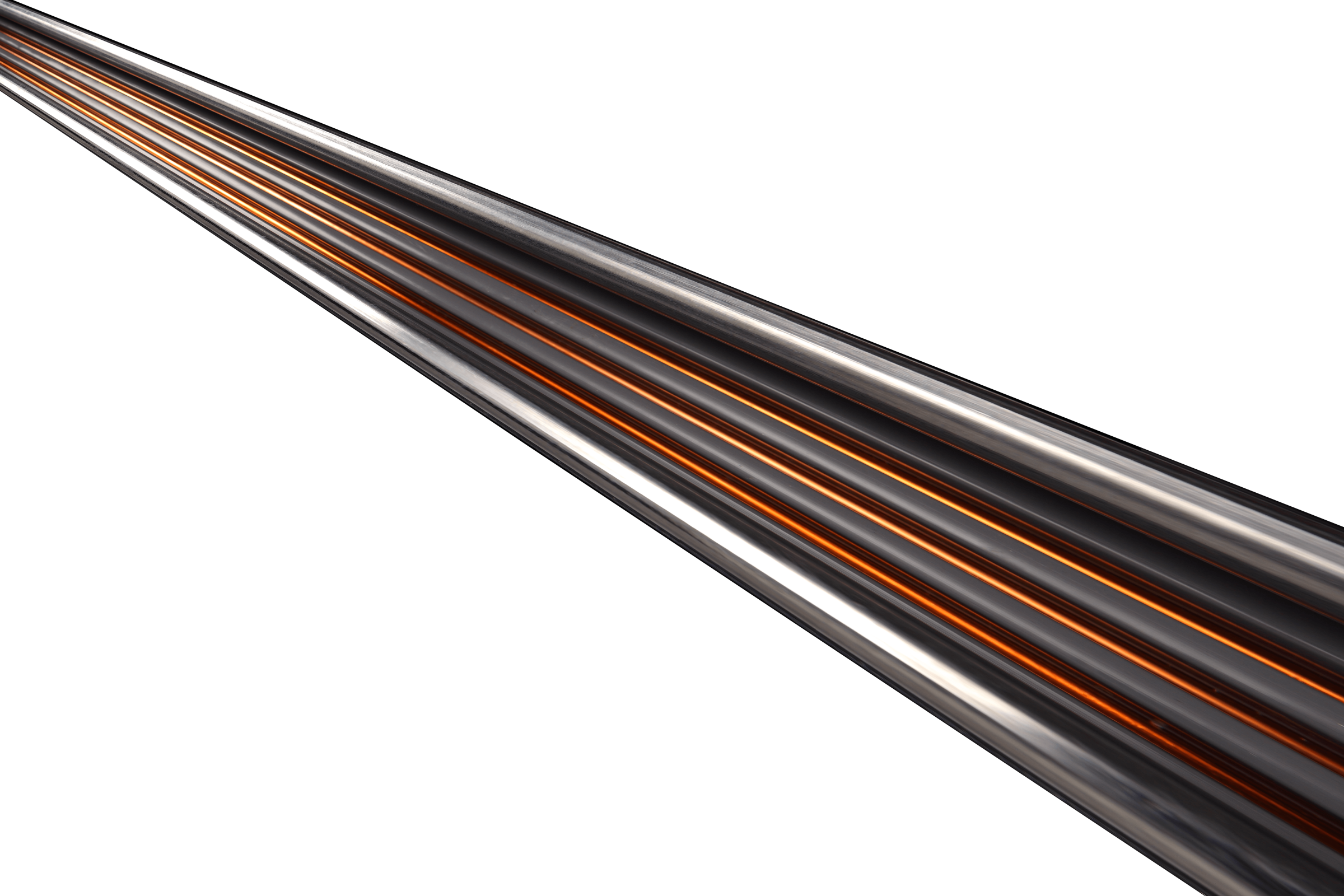

Tracks

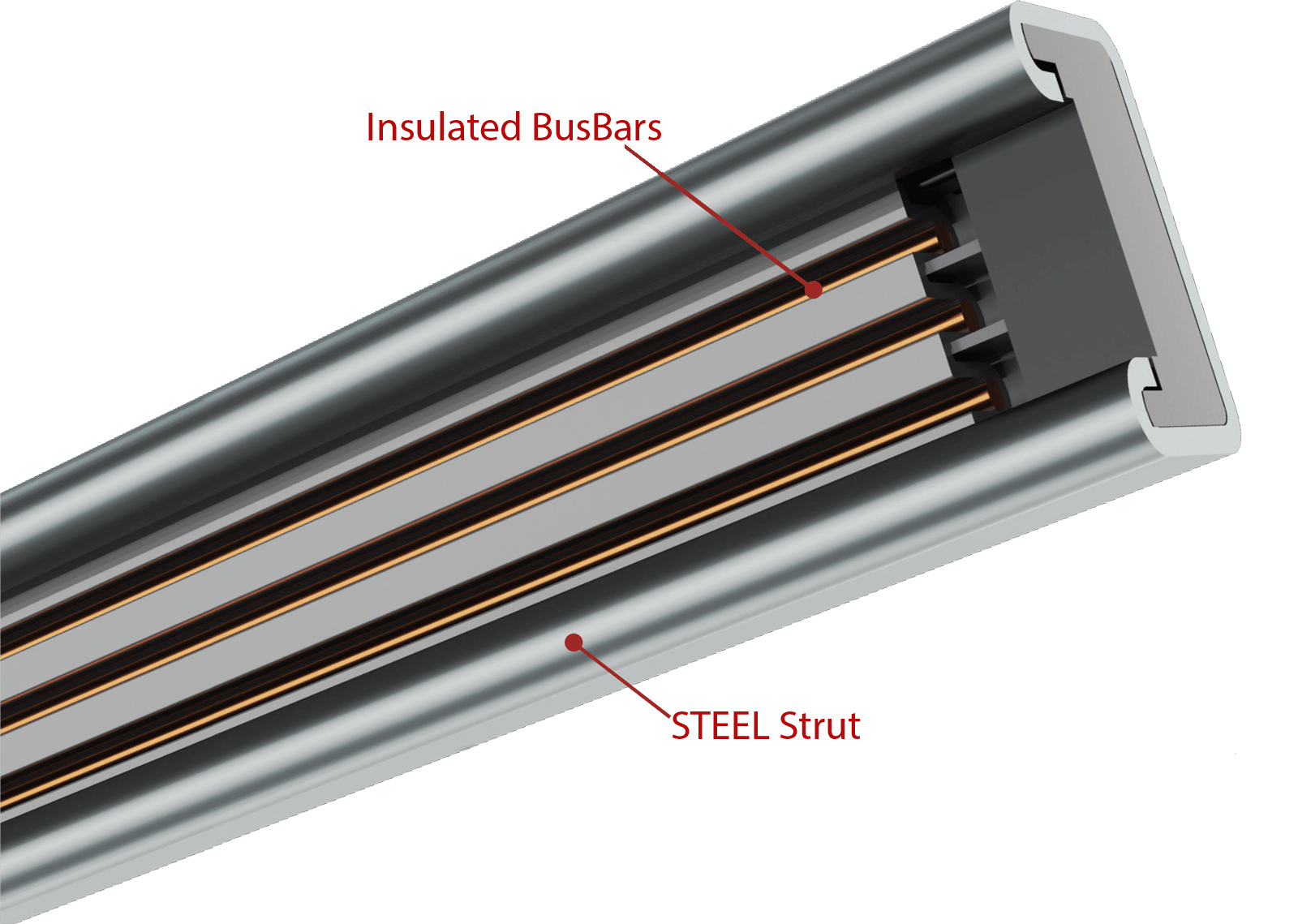

Pre-wired tracks are both the structural support and power conduits of the system. Such tracks are usually of high grade engineered materials. The tracks are usually of copper or aluminum busbars enclosed in a track enclosure; they are strong and a good conductor. The tracks can be set up in different configurations with joiners and crossover hardware to establish customized power distribution configurations.

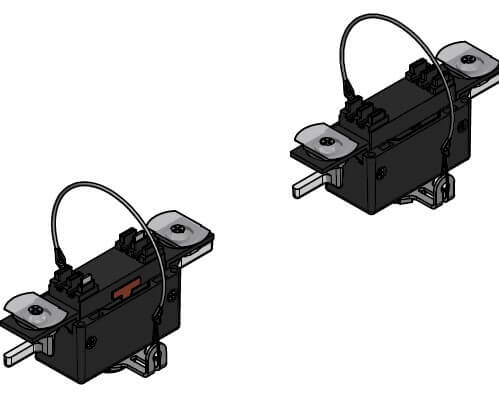

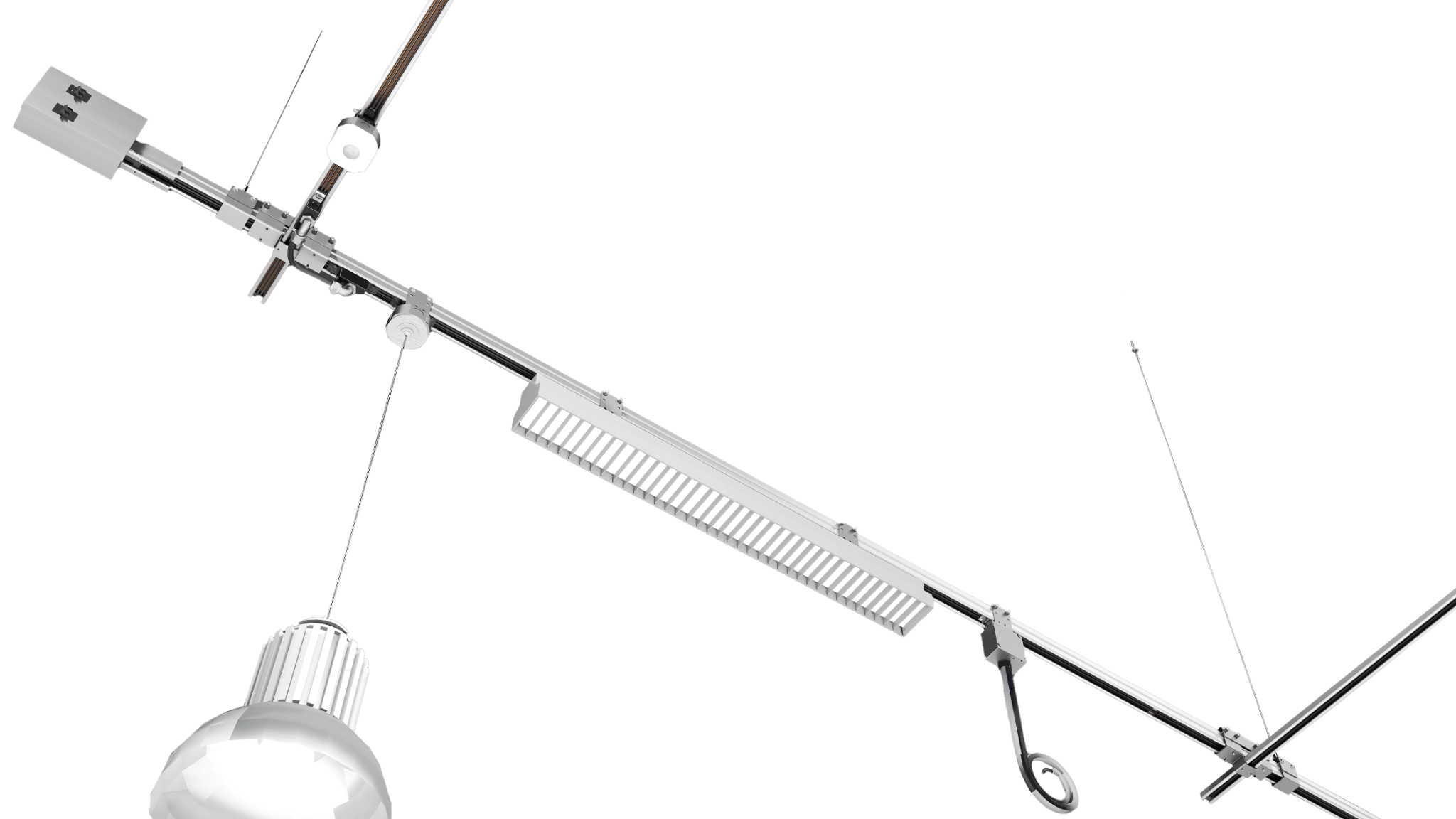

Factory Installed Fittings

The copper pins on a busway fitting electrify a device by tapping the copper in the tracks. This plug-and-play approach to lighting installation can greatly accelerate project timelines and cut labor costs.

To cut down on setup time and complexity, steel track busway plug-ins have the electro-mechanical busway fitting already attached to them when they arrive on site. Steel track busway power drops and lighting fixtures arrive on-site ready to install, cutting the risk of on-site wiring errors.

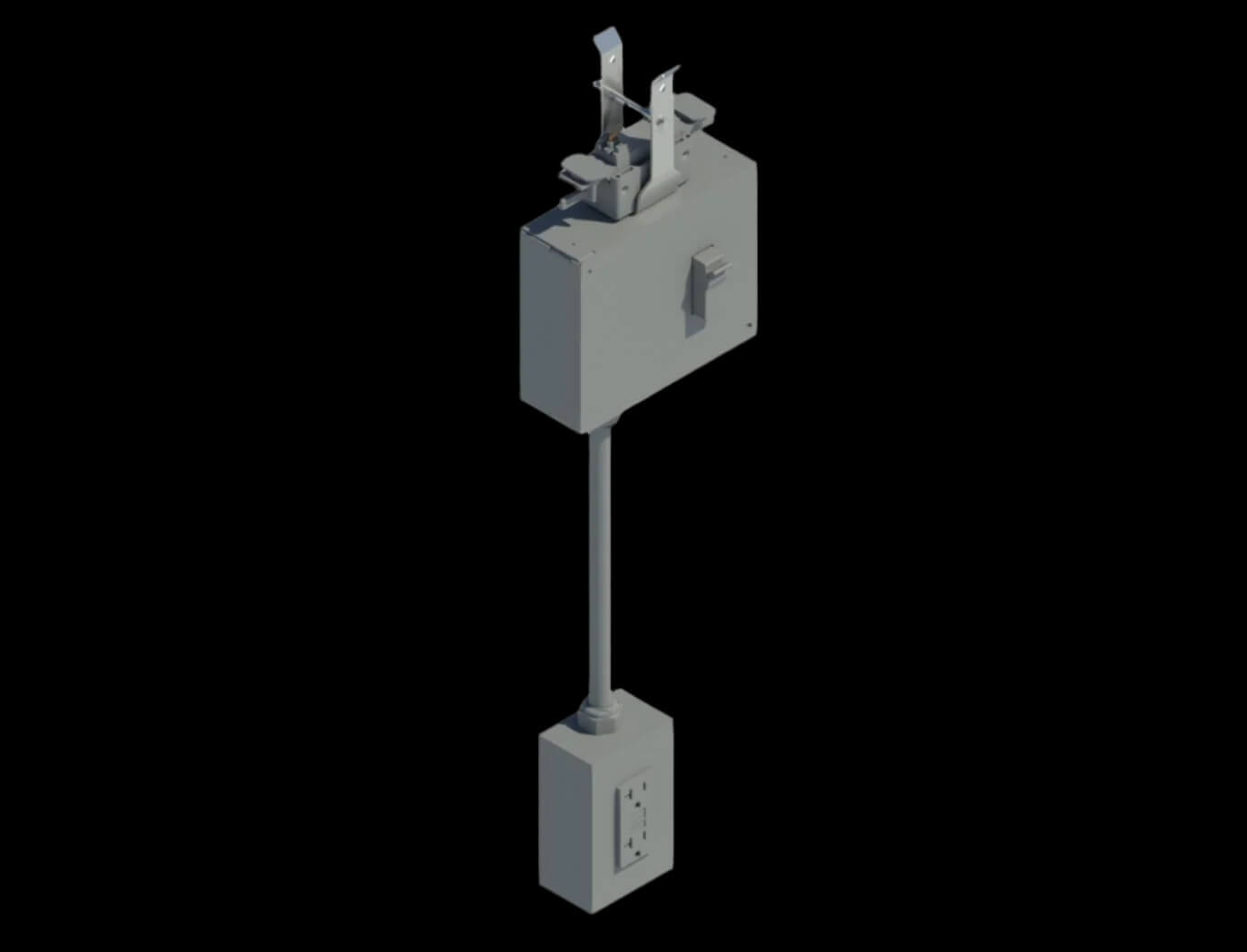

Plug-In Units

These are easily insertable plug in devices that give power connection anywhere along the busway. They include all the needs for power distribution such as circuit breakers and electrical outlets in one unit. They can be customized with different types of receptacles, circuit breakers, and drop cords. Plug in units can be inserted or removed without de energizing the busway for quick and safe modifications. One of the key advantages is that plug in units can be inserted or removed without de energizing the busway for quick and safe modifications.

How Track Busways Work

Power is distributed through the pre wired track sections by these systems. In minutes users can add or reposition plug in units along the pre wired tracks, making it ideal for dynamic environments where power requirements are frequently changing. This system eliminates the need for complex wiring and enables quick reconfigurations to meet the changing needs of the modern facility.

Continuous Access Slot

The entire length of the busway, the continuous access slot runs to offer flexible layout changes without service interruptions. An open channel design where anyone can insert or reposition plug in units anywhere ensures exceptional flexibility in power distribution.

Advantages Over Traditional Systems

These solutions are way better than the conventional power distribution methods in terms of flexibility, cost effectiveness and safety. These cutting edge systems are designed to offer solutions that are able to meet the changing power and/or lighting needs for an organization, by decreasing long term costs with a flexible system that improves workplace safety.

Drop Down Power Flexibility

This power distribution system is such that users are able to easily adapt to changes in layout and increasing power requirements. The system can be easily reconfigured by shifting the plug-in units or by adding new segments without the need for extensive rewiring or system shutdown. This is particularly useful in places like manufacturing facilities and data centers where equipment layout may change often.

The track busway power distribution systems are modularly constructed to enable businesses to quickly respond to changes in power distribution needs. Since they are plug-and-play in nature, extra power feeds and tap off units can be easily installed or removed without the need for the labor intensive rewiring or system disturbances. This scalability helps organizations to tackle their energy needs as they expand, transfer or rearrange their facilities.

Lighting Positioned Where Needed

You can easily reposition lights in response to a change in layout or task. Track busway lets you do that without having to re-wire your lighting setup to suit different work areas or new equipment. Whether it’s for a new production line or a more dynamic office space, you can easily adjust your lighting.

Cost-Effectiveness

Compared to conventional power distribution techniques, modular power distribution systems offer considerable cost savings. A track busway system is up to 90 percent faster to install than a conventional pipe and wire system, cutting on labor costs as well as downtime. The reusable nature of busway components also helps to cut long term costs as they are easily relocatable and reconfigurable.

However, traditional wiring methods may involve labor intensive and material based installation processes, where track busway systems offer simple and timely installation with minimal downtime. Modular components do not call for conduit and cable installations because they can be easily connected and disconnected. So, businesses pay less for installation costs and encounter minimal interruptions when the system is upgraded or expanded.

Safety

It makes the workplace more safe by eliminating the need for long cable runs and reducing the chance of tripping. The systems contain various safety features including; automatic grounding of the plug in units before electrical connection and a design that prevents incorrect installation. To be listed to UL standards, track busway systems must be finger safe.

Scalability

These electrical busbar systems are highly scalable in that they can easily expand as power needs increase. Users can easily add new busway sections or upgrade plug-in units to handle increased power demands without replacing the total system. This scalability of the power distribution infrastructure ensures that it is able to grow with the needs of the facility, providing a future proof solution.

Conclusion

New and modern solution for power distribution challenges are these systems, and they present flexibility and efficiency that cannot be matched. These solutions are ready to easily and reliably meet changing power needs as workplaces evolve. Find out more about the benefits of track busway systems in our detailed blog post: Key Benefits of Track Busway Systems.